Crankcase, Under Pressure

Welcome to your ultimate PCV guide, courtesy of the team at Damond Motorsports.

Before we go over the variety of oil catch can set-ups, it’s best to explain why you need a positive crankcase ventilation (PCV) system, how it works, and the role it plays on your car.

If you aren't familiar with how a four stroke engine works, take a look here. Depending on you specific engine, the pressure inside the combustion chamber during the compression, and power strokes can be thousands of PSI. Though the piston rings do a relatively good job at sealing this pressure into the combustion chamber, some of the combustion gasses make their way past the rings into the crankcase. This process, and the gases, is called blow-by.

The PCV system is in place on your vehicle to allow the blow-by gasses from the combustion process to evacuate the crankcase. Engine performance, emissions, and reliability are all impacted by how your PCV system functions. Improper release of blow-by gases can result in poor efficiency, erratic behavior, and even mechanical issues like blowing out a dipstick, or rear main seal.

So how does a PCV system work? A stock PCV system will take the blow-by from the combustion process, filter it, and recirculate it back into the intake tract. It does this under all engine conditions, idle, cruising, heavy load, boost, engine braking, etc. All components of the PCV system need to work as one, to ensure the recirculation of the blow-by goes smoothly.

The main PCV components include:

-An oil separator or two: A means of separating the oil from the air. Many Mazda and Ford engines are equipped with two; the oil separator on the engine block, which our PCV plate replaces, and the valve cover.

-A PCV valve: A means to control the flow of air from the crankcase.

-Intake manifold port: A means to pull a vacuum.

-Intake tract port, pre-turbo: A means to pull a vacuum under boost.

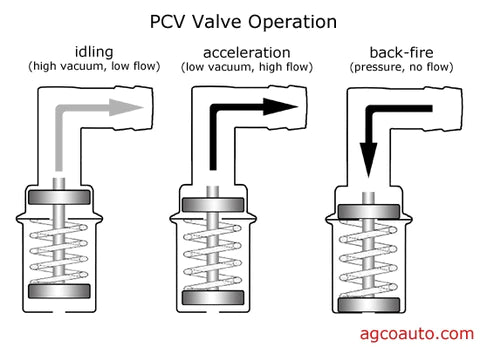

The PCV system uses the PCV valve to ensure proper operation of the system under various conditions. This valve’s job is to strictly manage the flow of air through the crankcase under any vacuum condition, and to prevent intake backfires or boost from entering the crankcase. Under various increments of intake vacuum, the PCV valve adjusts to allow only the amount of flow needed to properly evacuate the blow-by.

Here’s a graphic showing some of the common operations of the PCV valve.

First under high vacuum, such as idling or engine braking, the plunger inside the valve is fully opened from the high vacuum in the intake manifold. This restricts the amount of air pulled from the crankcase into the manifold, as under these conditions blow-by is quite low. If the vacuum is high enough, and blow-by low enough, fresh air from the intake tract may come into the valve cover, and the crankcase.

Next we see a cruising condition. When cruising at mid load, there is not as much vacuum from the manifold, but blow-by is more prominent. The plunger inside the valve is pulled open to a middle position. The middle position of this valve allows a larger flow area than the fully open position. This allows the additional blow-by gases to escape into the manifold, despite having lower vacuum to pull them.

Lastly we see a no vacuum condition, an intake backfire or boost, where the valve closes to prevent additional pressure from entering the crankcase. With a closed PCV valve, the valve cover to intake tract is the main means of evacuating blow-by under boost conditions. Under boost is when the most blow-by can occur, so it has to be evacuated from the crankcase efficiently to avoid excess crankcase pressure. The intake helps evacuate blow-by gasses by pulling a slight vacuum on the crankcase. Since the PCV valve is closed on the other end of the system, there is no fresh air source. This is generally enough to properly evacuate the crankcase of blow-by.

By now, you hopefully understand the importance of the PCV system, and how the pieces work together to keep crankcase pressures under control under all conditions the OEM designed for. However, this system isn’t perfect.

The most common concern with a PCV system is that the blow-by gases that come out of the crankcase, and into the intake side of your engine, have entrained oil that comes along with them. This oil can coat intakes, intercoolers, even valves with oil buildup. It can lead to loss of efficiency, power, or even reliability, among other things. A solution to this is to add in a filter, or a means to further separate the entrained oil in the blow-by. This is where an oil catch can comes into play, as an OCC is a means of filtering.

Another concern is increased crankcase pressure from engine modifications, and tuning. Tuned cars running higher than stock boost levels will see an increase in cylinder pressures, and more blow-by because of it. This leads to higher crankcase pressure, and this added flow may be more than the OEM PCV system can relieve. If you’ve ever seen a dipstick pop out, and spew engine oil all over an engine bay, it’s because the excess crankcase pressure was not allowed to evacuate fast enough. Excess crankcase pressure can also harm performance, and engine efficiency. With lower crankcase pressure you prevent oil from pushing past the rings making it’s way into the combustion chamber. This makes for a cleaner, more efficient air and fuel burn.

In contrast from crankcase pressure, you also do not want is excess vacuum on the crankcase, as excess crankcase vacuum can be harmful to your engine. This vacuum can pull oil away from important components such as the oil control rings, piston wrist pins, and even the camshaft oiling surfaces. Instead of blowing out seals with excess pressure, excess vacuum can pull on seals like the rear main and front crankshaft seals, causing leaks. This is why incorporating a PCV valve is beneficial for controlling the amount of vacuum flow on the crankcase.

We hope you enjoyed our intro into basic PCV systems. Please check out our continuation of this blog here, where we further explaining different PCV setups with OCCs and our new PCV plate.

Leave a comment