Bye-Bye Blow-By

To show what can be done to avoid excessive oil in the intake, and to relieve excess crankcase pressure, here’s some diagrams of common oil catch can set-ups, including set-ups with additional crankcase ports, via a PCV plate.

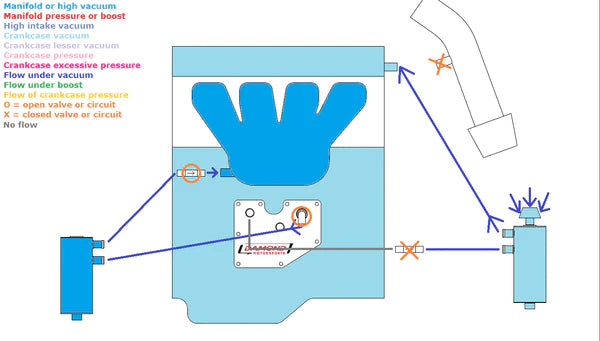

First let’s look at the stock system under both boost and vacuum. Under vacuum the intake manifold pulls a vacuum on the crankcase via the PCV valve. The PCV valve meters the flow of air on the crankcase, getting a fresh air source via the valve cover to intake connection. Under boost, the intake tube pulls a slight vacuum onto the crankcase, and the PCV valve attempts to prevent boost pressure from entering the crankcase. However, the factory PCV valve may leak under boost, as there is not a true seal in the valve. Some of the pressure can make it past the valve, and into the crankcase.

Pros:

-No modification needed

-Sufficient to maintain proper crankcase evacuation for a stock, or lightly modified engines

Cons:

-Entrained oil in blow-by allowed into the intake manifold, and intake tract

-Does not address excess crankcase pressure on high boost, tuned cars

-PCV valve prone to leaking can further increase crankcase pressure

Recommend for:

-Stock cars or vehicles with little modifications, where the effects of oil contamination are not a concern to the owner

Here we have our standard Oil Catch Can kit setup: An OCC is put in place between the intake manifold port and PCV valve, to capture the entrained oil in the blow-by. A check valve is in place to prevent boost from entering in the system, mainly to prevent it from reaching past the PCV valve. To learn more about how our OCC kit prevents oil from recirculating into the intake, click here, and select your car.

Pros:

-Entrained oil in blow-by captured by the OCC

-The check valve helps to prevent boost past the PCV valve, thus reducing crankcase pressure and blow-by out of the valve cover

-Simple system, effective for most stock, lightly tuned cars

Cons:

-Minor modification needed

-Does not address excess crankcase pressure on high boost, tuned cars

Recommended for:

-Stock engines, or vehicles with minor modifications, where the effects of oil contamination are a concern to the owner

Here is our OCC kit with the Vent To Atmosphere option. We incorporate a check valve into the OCC, concealed by an air filter, to vent excess crankcase pressure that can make its way past the PCV valve under conditions of higher crankcase pressure. To learn more about how our VTA kit helps vent additional crankcase pressure, click here.

Pros:

-Entrained oil in blow-by captured by the OCC

-The check valve helps to prevent boost past the PCV valve, thus reducing crankcase pressure and blow-by out of the valve cover

-Simple system, effective for most stock, lightly tuned cars

-VTA valve is incorporated into the OCC and concealed by the air filter for a clean look

-VTA will vent only excess pressure in the OCC that makes its way from the crankcase past the PCV valve

Cons:

-Minor modification needed

-VTA may not be enough to vent the crankcase on highly boosted applications.

Recommended for:

Vehicles running a stock turbo with high boost, modified stock turbos (CS, BNR, etc.), and GT28 series turbos.

Here is a setup that relies strictly on the intake system to evacuate the crankcase, and incorporates an OCC. Under idle, only a slight vacuum is pulled via the intake tube. This can result in crankcase pressure under idle conditions. Under boost the intake can pull a stronger vacuum to evacuate the crankcase, however it may not be sufficient enough to properly evacuate the crankcase.

Pros:

-Entrained oil in blow-by captured by the OCC from both the oil separator and valve cover ports

-Simple system

Cons:

-Minor modification needed

-Not sufficient for venting the crankcase under vacuum, as there is little vacuum pulled from the intake under idle. This generally leads to crankcase pressure at idle, where the oil coming from the turbo cannot drain properly, leading to oil seeping past the turbo seals and into the exhaust.

-PCV valve rendered useless for controlling airflow, as there is little air flow on the valve

Not Recommended

Here is a fully vented setup. We can see an OCC to capture the oil in the blow-by. Under engine vacuum, no vacuum is present on the crankcase. This can lead to excessive crankcase pressure, even just under idle. Under boost the crankcase pressure increases, and may not be able to find its way out of the system quick enough, as there are restrictions on the system, such as the PCV valve, preventing maximum flow.

Pros:

-Low cost, especially if OCCs are not used

Cons:

-Traces of oil in the engine bay, especially if OCCs are not used

-Not sufficient for venting the crankcase under vacuum, as there is little vacuum pulled from the intake under idle. This generally leads to crankcase pressure at idle, where the oil coming from the turbo cannot drain properly, leading to oil seeping past the turbo seals and into the exhaust.

-PCV valve rendered useless for controlling airflow, as there is little air flow on the valve

Not recommended

Now here’s where the fun begins… Dual OCC set-ups, and using a PCV plate for additional flow, and venting.

First Dual OCC set-up is fairly simple. The closed OCC ties the intake manifold and PCV valve, whereas the second OCC with VTA valve ties together the intake tube to valve cover ports. Under vacuum the system operates similar as to having just 1 sealed OCC on the intake manifold to PCV valve connection. Under boost the intake tube pulls a vacuum on the crankcase, however if excess crankcase pressure is present in the system, the second OCC is able to vent the excess pressure via the VTA valve.

Pros:

-Entrained oil in blow-by captured by both OCCs

-The check valve helps to prevent boost past the PCV valve, thus reducing crankcase pressure and blow-by out of the valve cover

-Simple dual OCC system, effective for many moderately tuned cars

VTA valve is incorporated into the second OCC and concealed by the air filter for a clean look

-VTA will vent excess pressure in from the crankcase, if the intake tube is unable to fully evacuate the system

Cons:

-Minor modification needed

-Additional ports may be needed for flow to vent the crankcase on highly boosted applications

Recommended for:

Vehicles running in excess of 24psi on a stock turbo, modified stock turbos (CS, BNR, etc.), and GT28 series turbos.

Here is a setup that uses the secondary OCC to vent pressure, along with tying in the valve cover port, to not allow blow-by into the intake tract as that is now capped off. There is no VTA valve in this system, as the OCC is just straight vented. This is due to the system needing a fresh air source under manifold vacuum conditions, and the vented OCC becomes that source. Unfortunately in doing so, un-measured air is now entering the PCV system during manifold vacuum conditions, basically causing a vacuum leak. Extra tuning may be needed to mask the leak.

Pros:

-All oil blow-by captured by the OCCs

-The check valve helps to prevent boost past the PCV valve, thus reducing crankcase pressure and blow-by out of the valve cover

-Effective for moderately to highly tuned cars

-Vented OCC used to relieve excess crankcase pressure, and allow airflow through the system under idle

-PCV plate in place to add additional ports for evacuating the crankcase, in a convenient package

Cons:

-Moderate modification needed

-More complex system, needing additional components

-Un-measured air flow under vacuum, additional tuning required

Recommended for:

Vehicles running big turbos, where excess crankcase pressure is present, with intake tubes that do not have a PCV port, and where tuning can be preformed to negate the un-measured air flow

Here is a pretty basic dual OCC setup where the secondary OCC is strictly for venting excess crankcase pressure. This system is best for venting excess pressure, as both ports on the PCV plate are used, allowing for a less restrictive flow path. The intake tube to valve cover port is retained, to pull a vacuum on the crankcase under boost. Once that vacuum is succeeded by crankcase pressure, the VTA OCC will vent the excess pressure, before oil blow-by contaminants can make their way into the intake tube.

Pros:

-Oil from blow-by captured by the OCCs

-The check valve helps to prevent boost past the PCV valve, thus reducing crankcase pressure and blow-by out of the valve cover

-Simple dual OCC system, effective for most highly tuned cars

-VTA valve is incorporated into the second OCC and concealed by the air filter for a clean look

-VTA will vent excess crankcase pressure, and using both OCC ports allows for least restrictive air flow

-PCV plate in place to add additional ports for evacuating the crankcase, in a convenient package

-No un-measured air flowing in under vacuum

-Intake port still in place to pull a vacuum under boost conditions to help evacuate the crankcase, and since the VTA OCC will vent at the sign of crankcase pressure, next to null oily blow-by makes its way up to the valve cover and into the intake

Cons:

-Moderate modification needed

Recommended for:

Vehicles running big turbos, where excess crankcase pressure is present

Here is a setup where all PCV components are utilized along with OCCs to filter the blow-by. This is the most complex system, as there are more components to tie the PCV system all together, along with the additional ports added on the PCV plate. While the set-up mentioned prior can relieve excess crankcase pressure, this set-up can as well, and ties in the valve cover port to intake tube, to totally prevent oil contaminates from blow-by in the intake. Under extreme pressure there is a check valve with a filter added on the PCV plate, that will vent the excess crankcase pressure exceeding 1psi.

Pros:

-All oil blow-by captured by the OCCs

-The check valve helps to prevent boost past the PCV valve, thus reducing crankcase pressure and blow-by out of the valve cover

-Effective for most highly tuned cars

-VTA valve is incorporated into the second OCC and concealed by the air filter for a clean look

-VTA will vent excess crankcase pressure, and prevent un-measured air flowing in

-Intake tube port still in place to pull a vacuum under boost conditions

-PCV plate in place to add additional ports for evacuating the crankcase, in a convenient package

Cons:

-Moderate modification needed

-Most complex system, needing many additional components

Recommended for:

Vehicles running big turbos, where excess crankcase pressure is present, and where excess oil is present out of the valve cover

So what does this mean to you, or how you want to set up your PCV system? Well, we designed our OCCs and components to where VTA valves, vents and blocks could be added on or taken away later. If you already have our existing OCC kit, and wish to upgrade to a dual kit, you already have some of the components needed to do so, and can easily convert to a different setup.

If you wish to create your own diagram, and send it to us for advice or questions, feel free to do so using this blank template. Add in what you can, or how you’d like to plumb your PCV system, and we should be able to give you a general idea of how the system will perform under different engine conditions. If you do decide you want a custom kit, we can help you put together what you’ll need, and we offer components individually to help you get the most optimal PCV system for your car’s needs.

Comments

Leave a comment