Too cool or not too cool, the Damond Motorsports engine oil cooling blog

With the release of our oil cooler kits, we wanted to go into more detail on oil cooling. We love sharing what we know with our customers so they can make informed decisions based on data and facts.

When it comes to oil cooling, we see there to be a higher want than a need for cooling. Let us be clear: most of the cars we work on or sell products to, do not need an upgraded oil cooler. You probably don’t need one for your street car. It is when you start talking about long durations and repeated power cycles like a road course when the story changes.

A common misconception that we see all the time is that cooler oil is better. You are running your car hard, so you want to keep it cooler than normal, right? Not Exactly. What you want to do is keep the engine at a proper running temperature. In terms of oil, you want to achieve a temperature that will help burn-off condensation from within the crankcase, while maintaining proper oil pressure for your bearings.

Condensation or water in the crankcase can lead to accelerated engine component wear. This happens because, unlike oil, water cannot take the pressure and temperature that you get between loaded surfaces like bearings and gears. It also does not provide the lubricity that you need between those surfaces to keep them sliding against each other rather than wearing. The reality is that there is always some amount of water in your crankcase. Water is a byproduct of combustion, and any blow-by that gets into your crankcase carries water vapor in it. When your engine cools off, that vapor can even turn into liquid water that sits at the bottom of your oil pan. The trick is to keep your oil warm enough to effectively keep all the water as vapor rather than let it turn into liquid. Water boils off at 212°F, but will evaporate at lower temperatures. Generally speaking, you want to keep these engines above 180°F to keep the water as a vapor. Keeping it as a vapor will keep it moving out through your PCV system.

Thanks to advancements in technology and synthetic oils, many modern oils can run up to what were once considered very high temperatures without major degradation. It is not uncommon to see oil in racing scenarios reach temperatures above 300°F, which many oils can handle. That being said, 300°F is above the higher end of what you want to see in these engines, since pressure drop-off is going to be pretty significant. The oils and clearances in racing applications are designed to run that hot, which does not apply for most of us. They also just need to make it through one race before they’ll get fresh oil, a rebuild, or a new engine.

From actual track testing, we have figured the ideal engine oil temperature should be between 180°F and 260°F. Cooler than 180°F you are not going to be effectively burning-off the condensation in the crankcase. Above 260°F you will start to see lower oil pressures, especially at idle or very low engine speeds, where your oil pump is turning slower. Keeping the oil cooler on track also keeps the integrity of the oil for a longer life.

On a totally stock oil system on a relatively stock car, on the street you will generally see oil temps range from 180-220°F. With the same car on a road course, you may start to see temps above 270°F, and even close to 300°F on really hot days and/or extended sessions on track. Also, as you increase horsepower, you will generally see an increase in all temperatures, especially in a track setting. What is more is that none of these cars have actual oil temp sensors. The ST/RS platforms do feature an “oil temperature gauge”, along with being able to read “oil temperature” on data logging devices like the Cobb Access Port. However, this reading is a calculated value and NOT an actual oil temperature reading. It's best to take this reading with a grain of salt, since it can vary widely under various conditions. We have seen it vary anywhere from 2% to over 20% in our testing, against this calculated value.

What can be done to combat some of these extreme temperatures? Let’s talk coolers. If you have a Mazdaspeed3, Mazdaspeed6, Focus ST, Focus RS, your car comes from the factory with an oil cooler. If you have ever changed your own oil, you have probably seen it. Located above your oil filter housing is a little water to oil heat exchanger. This device features a stack of plates which allows oil and water to circulate though while being separate from one another. In doing so, the heat from the oil is transferred and “cooled” via the engine’s cooling system. For a street car, this little thing is perfect. It helps to keep oil temps somewhat in line with coolant temps, it is simple, it is well packaged, and it works relatively well. However, in track applications it is less than ideal. Because of its small size, it is only capable of a small amount of heat transfer, and that heat transfer is putting heat where we do not want it… back into the cooling system. Oil changes temperature at a much slower rate than water or engine coolant, so when your oil temps are high AF, it is going to take a lot of time and energy for the engine’s cooling system to absorb and dissipate that heat through that little cooler. Not ideal in a track setting.

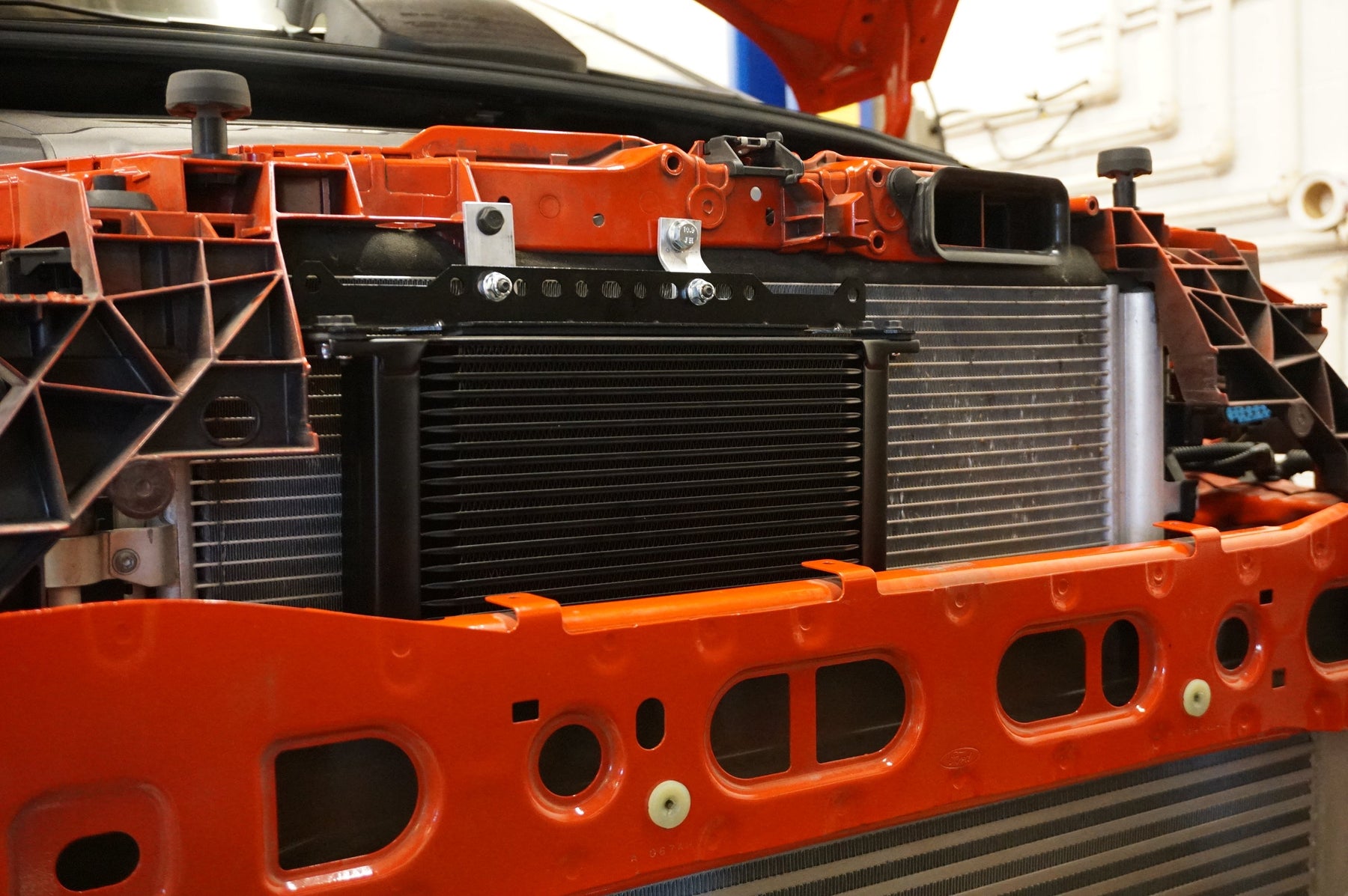

What about adding in an external air-to-oil cooler? These units are great for track use, and are commonplace on many high-end performance cars and racecars. They use airflow to transfer heat away from the oil via a stacked plate or fin and tube cooler similar to a radiator. Since there are many sizes available at various BTU ratings, you can easily spec a desired size for your engine and use. Air flow to these units is paramount, so packaging is important that the coolers have a large open-air source. You will commonly see these coolers up front positioned before the radiator and AC condenser, behind the front bumper. This is where a lot of folks start. Spin-on sandwich adapters make this an easy task, but they do sacrifice oil filter space, since they sit in-between the oil filter housing and oil filter. This means a shorter oil filter is needed. They do allow you to run an external air-to-oil cooler, but you are still left with the heat exchanger atop the oil filter housing. Not ideal, since that heat exchanger is still trying to move heat from the oil into the cooling system. Some of these spin-on kits can also restrict oil flow, leading to a slight pressure drop along with an audible oil pump whine.

Not all hope is lost though! What we have done here at Damond Motorsports is deleted that heat exchanger atop the filter housing with a high flowing adapter, allowing for the use of an air-to-oil cooler. This allows us to overcome a lot of the factory oil cooling limitations along with the shortcomings of a standard sandwich adapter. Since we mount this adapter on top of the oil filter housing, oil filter space is not compromised. You could even run the Damond adapter with the cartridge style filter housings found on the Mazdaspeed6 and 1st Gen Mazdaspeed3s. What’s more is that we have both sides of the adapter threaded. This allows for multiple configurations and line routing, and even the ability to run two oil coolers in parallel. Since running just one cooler is generally all that is needed, we will include plugs with our adapter that feature 1/8” NPT threads for oil temperature and pressure sensors.

Remember how important it was to get the oil temperature warm enough? To regulate oil temperature, we intend to supply our oil cooler kits with a remote high-flow oil thermostat. Without the oil thermostat, you would never see oil temperatures reach proper levels on the street to evaporate the water in the crankcase. Since we have deleted the factory heat exchanger, we have also seen a reduction in coolant temperatures on track. Temperatures for both oil and coolant also decrease at a faster rate. Oil does take a little longer to get up to operating temperatures, since we are no longer heating the oil with the engine’s cooling system.

What about actual data? We have been testing this set-up for years. It has been run on our shop track Mazdaspeed6 and Focus ST, along with other Mazdaspeeds and Focus RSs.

Here is some data we have gathered on our Focus ST, since it seems to be one of the hottest vehicles we have ever run on track.

With our oil cooler in place, we see a decent decrease in not only oil temperatures, but coolant temperatures as well. Over the course of a 30min track session, oil temps were just over 27°F cooler on average (35°F max). Now since we have deleted the factory cooler with our adapter, we are also seeing a drop in coolant temperatures. On average coolant temps were just over 12°F cooler (15°F max). This may not seem like much, but it was enough to not put the car into limp mode.

For our full oil cooler kits, we have decided on utilizing a 19 row cooler. We tested 16, 19, and 25 row coolers and found 19 to be the best for dual track/street duty and packaging with most front mount intercoolers. If your car is used in extreme cold climates, or only ran for short periods at a time, we would advise against running this type of kit.

We hope you have found this blog useful and informative on oil cooling for the Mazdaspeed and Focus platforms. If it is a part that you are seriously considering, do not hesitate to reach out to us with any questions. If not available already, we will shortly have oil cooler kits available for the Mazdaspeed3, Mazdaspeed6, Focus ST and Focus RS. If you find yourself more of a DIYer, we will soon have components for our oil cooler kits available, allowing you to build/piece together your ideal oil cooling system.

Leave a comment